Hot Stamping

Univacco’s product is safe and hazard-free for application to packaging. Our product complies with numerous national and international regulations on packaging, food contact materials, and toy safety. Each stage of production is checked according to respective quality inspection criteria and certifications.

What is Hot Stamping?

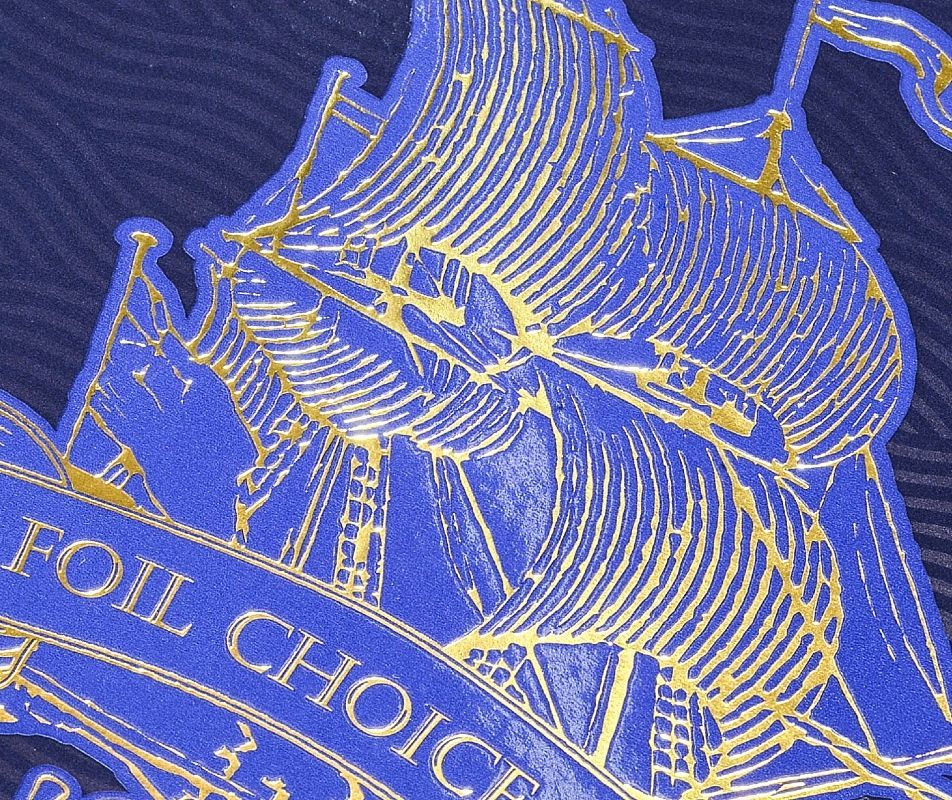

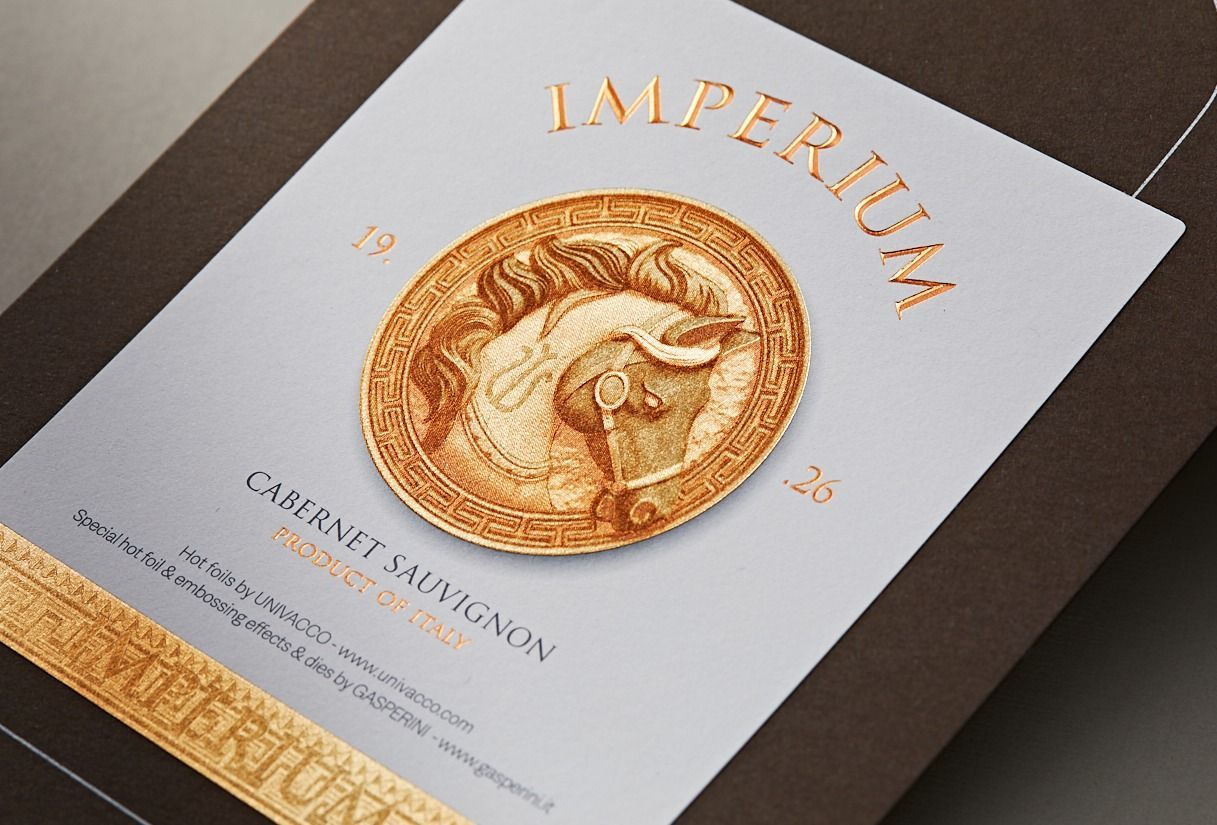

Hot stamping, also known as stamping foil, metallic foil, can be transferred to substrates with heat and pressure using metal dies. Hot stamping is unique in being able to offer incredible metallic shine, bright, mirror-like finishes to design. Differ from metallic ink printing, film after the stamping process (film blocking print method) creates a level of luxury.

Our Hot Stamping Products

Univacco supply a wide range of hot stamping for many substrates or materials, which are: coated paper, UV-vanished paper, water-base-vanished paper, uncoated paper, dry paper, carton, plastic self-adhesive label, OPP, PET laminate, PVC-based book cover, PU-leather and other synthetic leather.

Why Choose Hot Stamping?

Univacco’s hot stamping allows excellent release and creates consistent printing performance, which is suitable for either the fine detail or large area coverage.

Hot stamping from Univacco can run through all stamping machine types of the market known manufacturer in the graphic industries on Up-and–down/ platen/ clamshell/ letterpress presses, on cylinder presses and on rotary stamping systems.